Regional Platform on Next-Generation Composite Materials

Collaborative platform on sustainable manufacturing, eco-sustainability of products and processes for new materials and demanufacturing.

MARLIC (Marche Applied Research Laboratory for Innovative Composites) Project

27

Partners

€11.4M

Project Budget

30

Project length in months

2020-3

Project duration

Services

Research and Development

Pure or applied research, feasibility studies, technical and scientific support applied to the development of innovative composite materials, to promote eco-sustainable products and processes for the new materials.

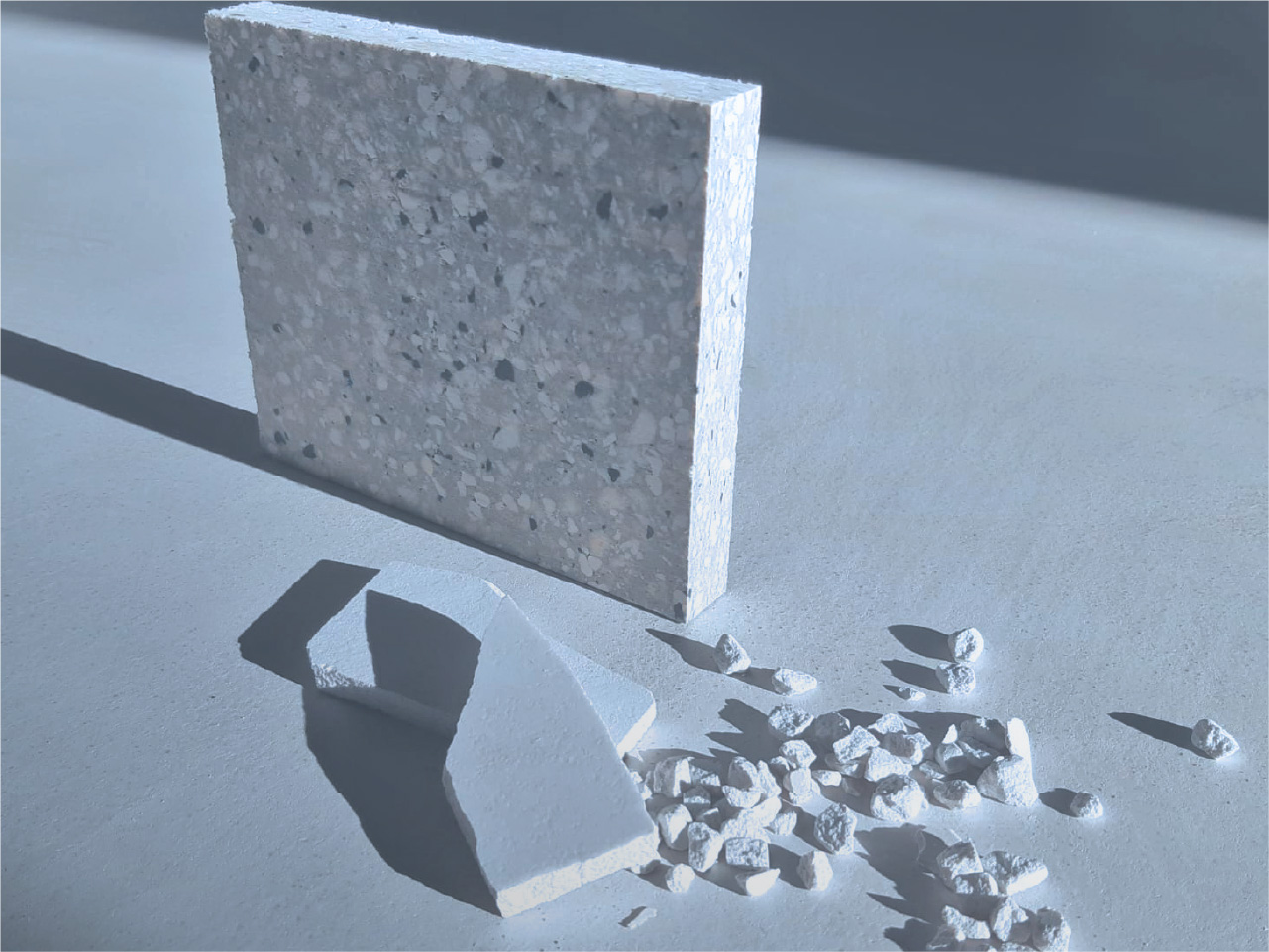

Analysis and Testing

Characterization of composite materials; analysis of defects with identification of causes and proposed solution strategies; optimization of production technologies.

Prototyping

Pre-testing and testing of the prototypes developed by companies, with training activities carried out in parallel with prototype development.

Design for Demanufacturing & Recycling

Support to companies in the design of new composite materials for demanufacturing and in the identification of possible strategies for the reduction, reuse, recycling and recovery of raw materials.

Training

Training on the technologies available in the laboratory, accessible to students and workers; consulting and orientation in the sector of polymer-matrix composite materials.

Laboratory Activities

Structural and Morphological Tests

Structural and morphological tests based on the recognition of specific chemical groups

Mechanical and Thermal Tests

Mechanical and thermal tests based on identifying correlations between chemical compositions and behaviours of composite materials.

Extraction and Purification

Extraction and purification from renewable sources other than food crops, such as food scraps and second-generation sources which cannot be used for food applications.

Organic Molecule Synthesis

Organic molecule synthesis through low environmental impact methodologies: the resulting molecules can be used as additives for a highly innovative composite product, characterized by the best features in terms of functionality, aesthetics, strength, versatility, reusability and recyclability.

Material Behaviour Tests

These tests are necessary to study the behaviour of composite material relative to processing and chemical composition parameters.

Ageing Tests

Accelerated ageing tests to study the correlation between life expectancy of a manufacture and environmental conditions.