Case Study

De manufacturing

Context

When manufacturing goods, a company generates by-products, such as discards and swarfs, as well as end-of-life (EOL) products. Discards differ by production typology, nature and disposal cost. Among the various materials, composites generate the most complexity, since they include different components, which are often difficult to separate and recover.

Problem

Year after year, the volume of discards increases, together with the related disposal cost and the effort made by companies to store, transform and recover them.

It is therefore imperative to reduce the amount of discards, to reuse them as secondary raw materials and to dispose only of the portion that cannot be recovered.

Solution

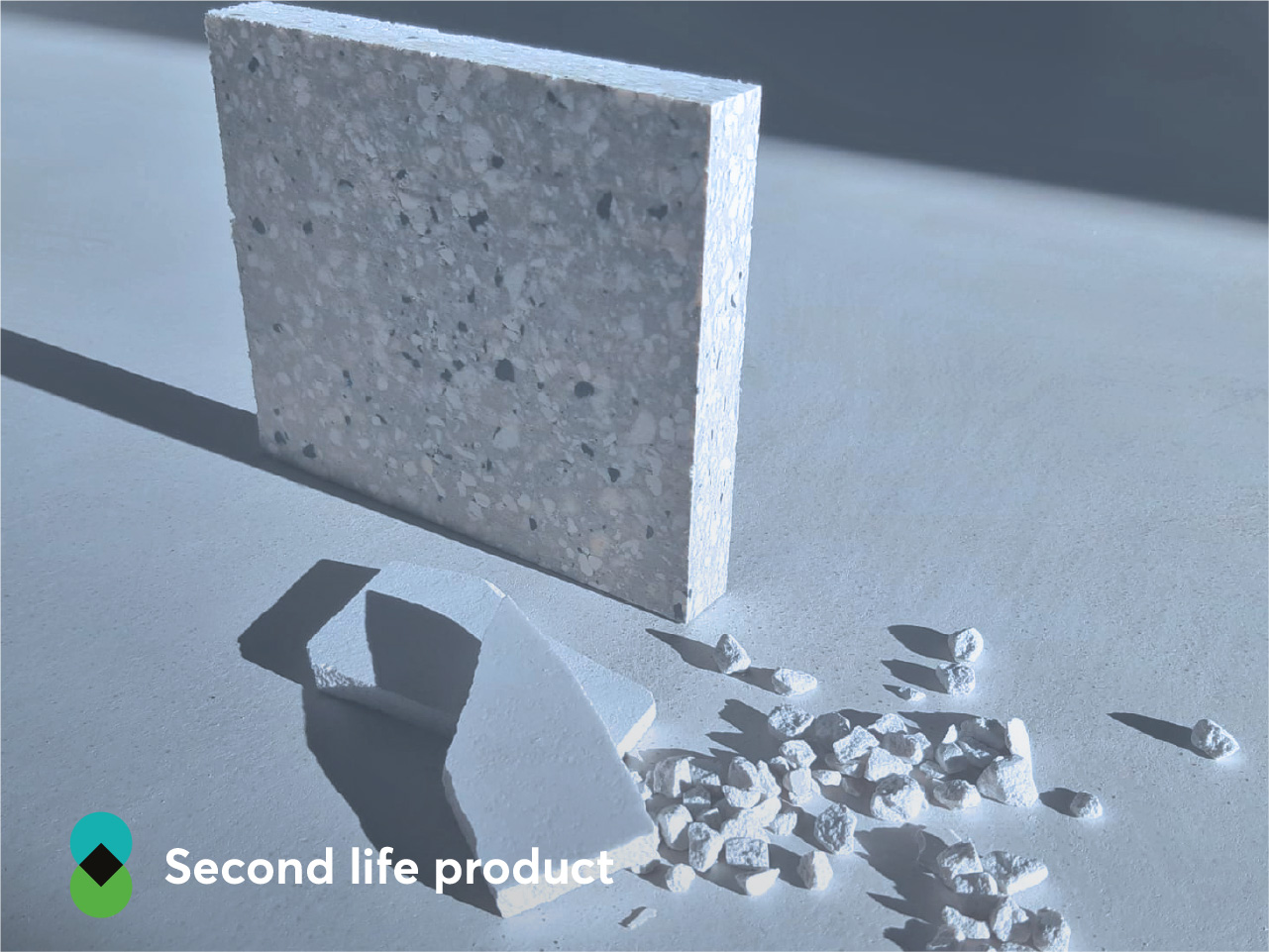

Innovative design with the application of Design For Demanufacturing (DFD) and Design For Recycling (DFR) methodologies and tools, and the use of easy-to-recover raw materials, recycled materials and eco-friendly processes.

After identifying the typologies and amounts of discards/swarfs and their features, the discards will be adequately treated to be reused for different productions or, as secondary raw materials, for the same production. The best recovery/transformation technologies shall be identified and their environmental impact shall be assessed.

Expected Results

Through the definition of innovative design methodologies, new uses of recovered materials and the manufacturing of prototype components, the whole know-how acquired shall be shared with project partners and research centres. A complete specification shall be given for the pilot components made with recovered materials, in order to evaluate their use in different manufacturing applications in the Marche Region.